Populer Products

Category

Blog & article

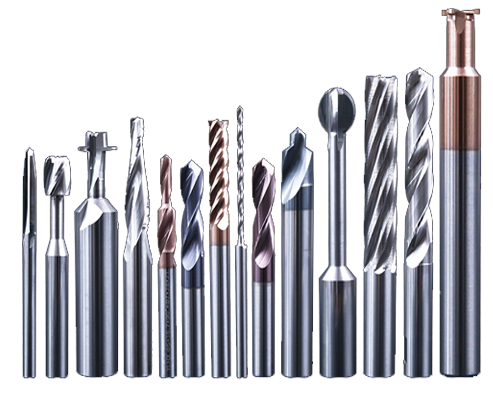

View all BlogMaintenance Guide for Drilling & Holemaking Tools

Proper maintenance of drilling and holemaking equipment is crucial for achieving high-quality results, reducing downtime, and extending the lifespan of the equipment. By following a structured maintenance program that includes daily checks, periodic inspections, and long-term storage preparations, manufacturers can ensure their drilling and holemaking equipment remains in top condition, ready to meet the demands of their production processes.

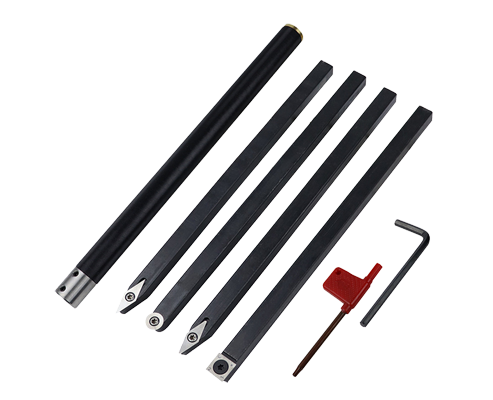

Daily Maintenance of Milling Cutters

This overview covers the essential aspects of daily maintenance for milling cutters, including cleaning, oil application, storage, avoiding improper use, regular inspection and sharpening, and safety precautions

Design of O-ring and its groove

The O-ring seal is a typical extrusion type seal. The compression ratio and tension of the cross-sectional diameter of the O-ring are the main contents of sealing design, which are of great significance for sealing performance and service life. The O-ring is generally installed in the sealing groove for sealing purposes.

What are the material types of O-ring seals?

O-ring is a circular rubber sealing ring with a circular cross-section, mainly used for mechanical components to prevent leakage of liquid and gas media under static conditions. In some cases. The O-ring can also be used as a dynamic sealing element for axial reciprocating motion and low-speed rotational motion.

Structural characteristics of O-ring

O-ring is a common sealing element with a circular cross-section shape, which has many excellent characteristics and applications. This article will introduce O-ring from the aspects of material selection, structural characteristics, sealing principle, and application fields.