Product catagories

-

Sealing

- Oil Resistant O-Rings

- Oil Resistant O-Ring Cord Stock

- Chemical Resistant O-Ring Cord Stock

- High Temperature O-Ring Cord Stock

- Chemical Resistant O-rings

- High Temperature O-Rings

- Water And Steam Resistant O-Rings

- High Vacuum Fluoroelastomer O-Ring

- Water And Steam-Resistant O-Ring Cord Stock

- O-Ring Backup Rings

- Fasteners

- Power Transmission

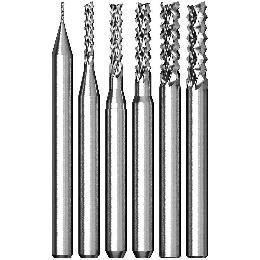

- Cutting Tool

- Spring

- Abrasives

- Electronic components

- Electrical & Lighting

- Auto Parts

- Motors

- Test and Measurement

- Tools and Equipment